Machine Tools

From installation, to repair of machine tools, Prime Machine has the knowledge and experience to get your machine running to its optimum capacity. When it comes to machine tools, the tolerances and accuracy are 100% dependent on using the correct procedures for setup and most accurate calibration methods possible.

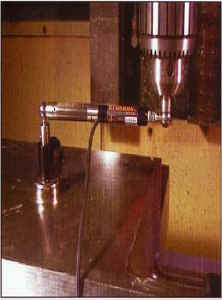

Renishaw Ballbar System

The Renishaw QC10 Ballbar System is based around a ball-ended bar-length transducer which is held magnetically and kinematically between machine spindle and a specially

designed magnetic base clamped to the machine bed. The CNC machine is programmed to describe a circle and the Ballbar transducer detects deviations which indicate inaccuracies in the machine tool path.From this data, the PC-based Renishaw Software can derive volumetric accuracy, Squareness values, repeatability, backlash, contouring ability, linearity XYZ and servo performance.

Using portable CMM for Machine Tool Calibration

The portable CMM or Laser Tracker is an excellent choice for calibration and analysis of machine tools. It is not size limited and can check wear, axis alignment, scale calibration, geometry, rotary axis calibration, level, and many more features with extreme accuracy.

- Alignment of machine base to <.001 in 30'